VACUUM FREEZE SERIES

CM-G37S/G57L

AUTO ROTARY ROUND TYPE ADVANCED VACUUM PEFRIGERATING & SHAPING MACHINE

- Features

- Specification Detail

- Lean Production Module

- Designing with the vacuum first and cooling next as for good uppers shaping to fit with the last perfectly.

- Designing the vacuum and cooling system into two separate independently boxes to make the production better efficiency.

- The circular of cooling cycle is from upward to downward, that makes excellent potent on inner shape setting.

- The rotary type conveyer belt can put more stuff, suitable for small production line.

- The turbo-compressor engine runs the production stably, durably and save energy efficiently.

- Designing with the rotating wheels provides production convenience for rearrangement needs.

| Specification Detail | CM-G37S | CM-G57L |

| Dimension | L1910*W2120*H1820m/m | L2110*W2320*H1820m/m |

| W/Packing | L2060*W2270*H2030m/m | L2260*W2470*H2030m/m |

| Power | 10.75P | 10.75P |

| Daily capacity of shoe or boots | 1000 pairs/8hrs | 1000 pairs/8hrs |

| Daily capacity riding boots | 1000 pairs/8hrs | 1000 pairs/8hrs |

- Saving energy,reduce carbon dioxide,and increases environmental protection.

- Save space with light body and exquisite outlook.

- The rotary type conveyer belt can save time and strength,as well as much more to dispose.

- Vacuum shaping,easy to operate and perfect finalizing.

- Design appropriate ergonomics and increase production efficiency.

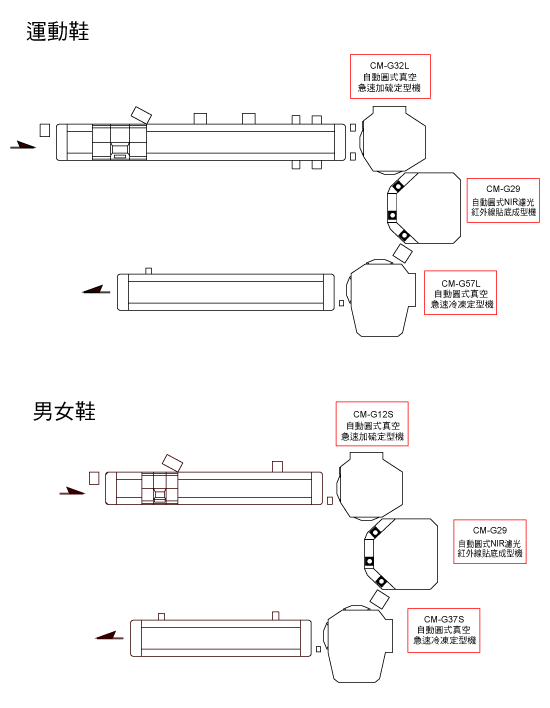

Flow chart:CM-G12S/G32L、CM-G29、CM-G37S/G57L