ASSEMBLY SERIES

CM-G29

AUTO ROTARY ROUND TYPE NIR CEMENT DRYING & ASSEMBLY SHAPING MACHINE

- Features

- Specification Detail

- Lean Production Module

- Designing with the low dazzle filter infrared ray light (NIR) made in Philips France, prevents from harsh to the eye. Heats up the glue floor inside and outside evenly with hot air circulation system to make the cement drying much more quickly and steady.

- Accurate thermostatic control system by adopting the analog 4-20mmA of SCR output that makes more precise for temperature controlling. The temperature tolerance in about ±1.5 °C.

- The patent stretchable type of shoe shelf can be suitable for various kinds of shoes.

- The round type conveyer belt by working on one side, suitable for small production line.

- Shoe tray uses intermittent and continuous double mold and double active mode, makes production line controlling effectively.

- Construct with the detect system to prevent electrical line break down. Detect the tube heating condition whenever needed to ensure the production quality.

- Designing with the rotating wheels provides production convenience for rearrangement needs.

| Dimension | L1950*W2027*H1670m/m |

| W/Packing | L2210*W2100*H2000m/m |

| N.W. | 235kgs |

| G.W. | 280kgs |

| Power | 18.25P |

| Capacity | 1000pair/8hrs |

- Saving energy,reduce carbon dioxide,and increases environmental protection.

- Save space with light body and exquisite outlook.

- The rotary type conveyer belt can save time and strength,as well as much more to dispose.

- Vacuum shaping,easy to operate and perfect finalizing.

- Design appropriate ergonomics and increase production efficiency.

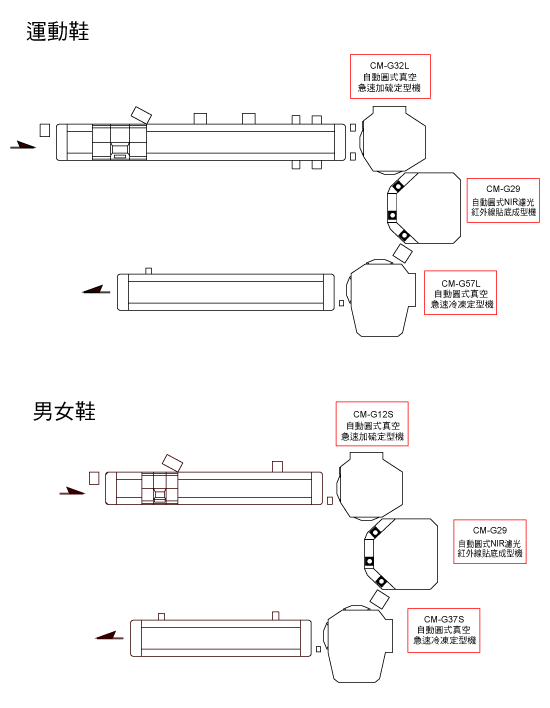

Flow chart:CM-G12S/G32L、CM-G29、CM-G37S/G57L