VACUUM SULFUR SERIES

CM-G12S/G32L

AUTO ROTARY ROUND TYPE RAPID VACUUM VULCANIZE & SHAPING MACHINE

- Features

- Specification Detail

- Lean Production Module

- Designing the vacuum and heating system into two separate independently boxes with sealed heating device. It provides well fit with the last and the satisfaction shaping by vacuum setting performance.

- Adjustable vacuum timing according to the material usage.

- The technique to vacuum first and refrigerate after sole pressing is to make the counter of the shoe more rigid and for good uppers shaping to fit with the last.

- Adding the steam air to natural leather or artificial leather during the process can upgrade the quality of uppers.

- Settle and maintain the shoes in a constant good shape.

- The rotary type conveyer belt can put more stuff, suitable for small production line.

- Designing with the rotating wheels provides production convenience for rearrangement needs.

| Specification Detail | CM-G12S | CM-G32L |

| Dimension | L1880*W1830*H1760m/m | L2080*W2030*H1760m/m |

| W/Packing | L2030*W1980*H1970m/m | L2230*W2180*H1970m/m |

| Power | 19HP | 19HP |

| Daily capacity of shoe | 1000 pairs/8hrs | 1000 pairs/8hrs |

| Daily capacity of riding boots | 1000 pairs/8hrs | 1000 pairs/8hrs |

- Saving energy,reduce carbon dioxide,and increases environmental protection.

- Save space with light body and exquisite outlook.

- The rotary type conveyer belt can save time and strength,as well as much more to dispose.

- Vacuum shaping,easy to operate and perfect finalizing.

- Design appropriate ergonomics and increase production efficiency.

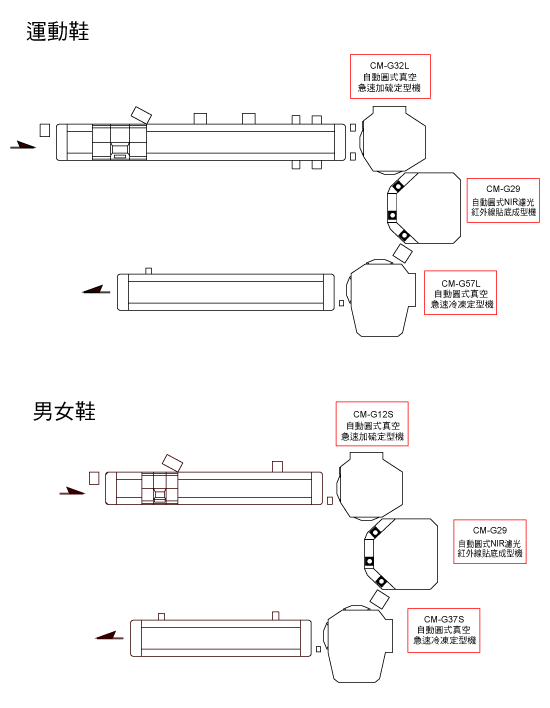

Flow chart:CM-G12S/G32L、CM-G29、CM-G37S/G57L