CEMENT DRYING AND ACTIVE SHAPING SERIES

CM-H19

NIR CEMENT DRYING AND SOLE ATTACHING MACHINE

- Features

- Specification Detail

- Lean Production Module

- Designing with the low dazzle filter infrared ray light (NIR), prevents from harsh to the eyes. Heats up the glue floor inside and outside evenly with hot air circulation system to make the cement drying much more quickly and steady.

- Accurate thermostatic control system by adopting the analog 4-20mmA of SCR output that makes more precise for temperature controlling. The temperature tolerance in about ±1.5 °C.

- Separate three divisions of outsole, insole and upper with individual temperature controlling. Main heating from NIR, and assist from electric heating tube.

- Detects the material temperature by infrared ray lights as to instant amend the temperature compensation and to ensure the production quality.

- Working on single side to save space and reduce labor cost as suitable for elite team production line.

| Dimension | L1345*W1150*H1570m/m |

| W / Packing | L1500*W1300*H1800m/m |

| N.W. | 266kgs |

| G.W. | 482kgs |

| Power | 14.6HP |

| Capacity | 200pair/8hrs |

- Saving energy,reduce carbon dioxide,and increases environmental protection.

- Save space with light body and exquisite outlook.

- Appropriate ergonomics achieve better production.

- Automatic material in and out design is quick and convenient.

- Single side loading to save space and reduce labor cost.

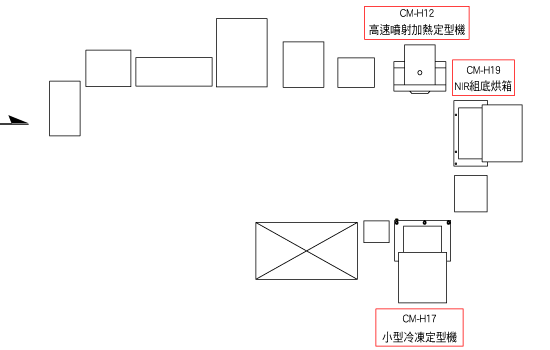

Flow chart:CM-H12、CM-H17、CM-H19